Welding machines and fit-up equipment for turbine rotors and housings

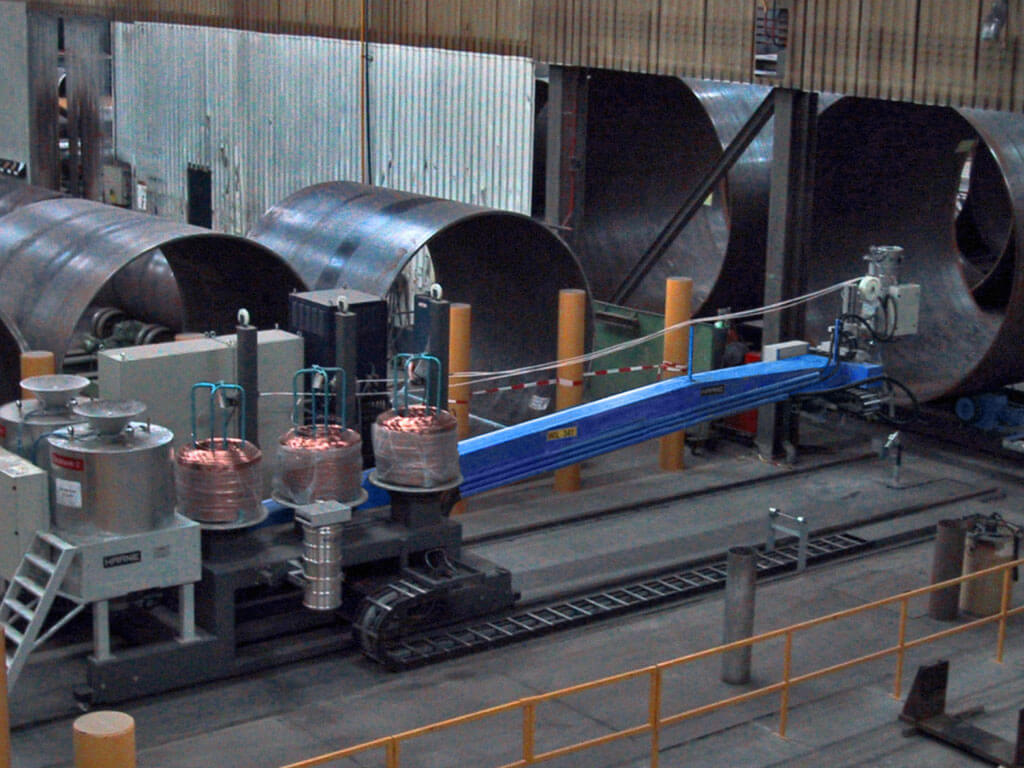

HAANE welding systems supplies welding and alignment equipment for production of turbines used in coal, gas and nuclear power plants. This includes the turbine rotor and as well the turbine housing.

Heavy valves for high pressure applications can be welded by using the HAANE Multi-Mode welding head: SAW welding using single wire and alternating twin wire with no need for changing any equipment components.

For renewable power we offer solutions for production of windmill components.

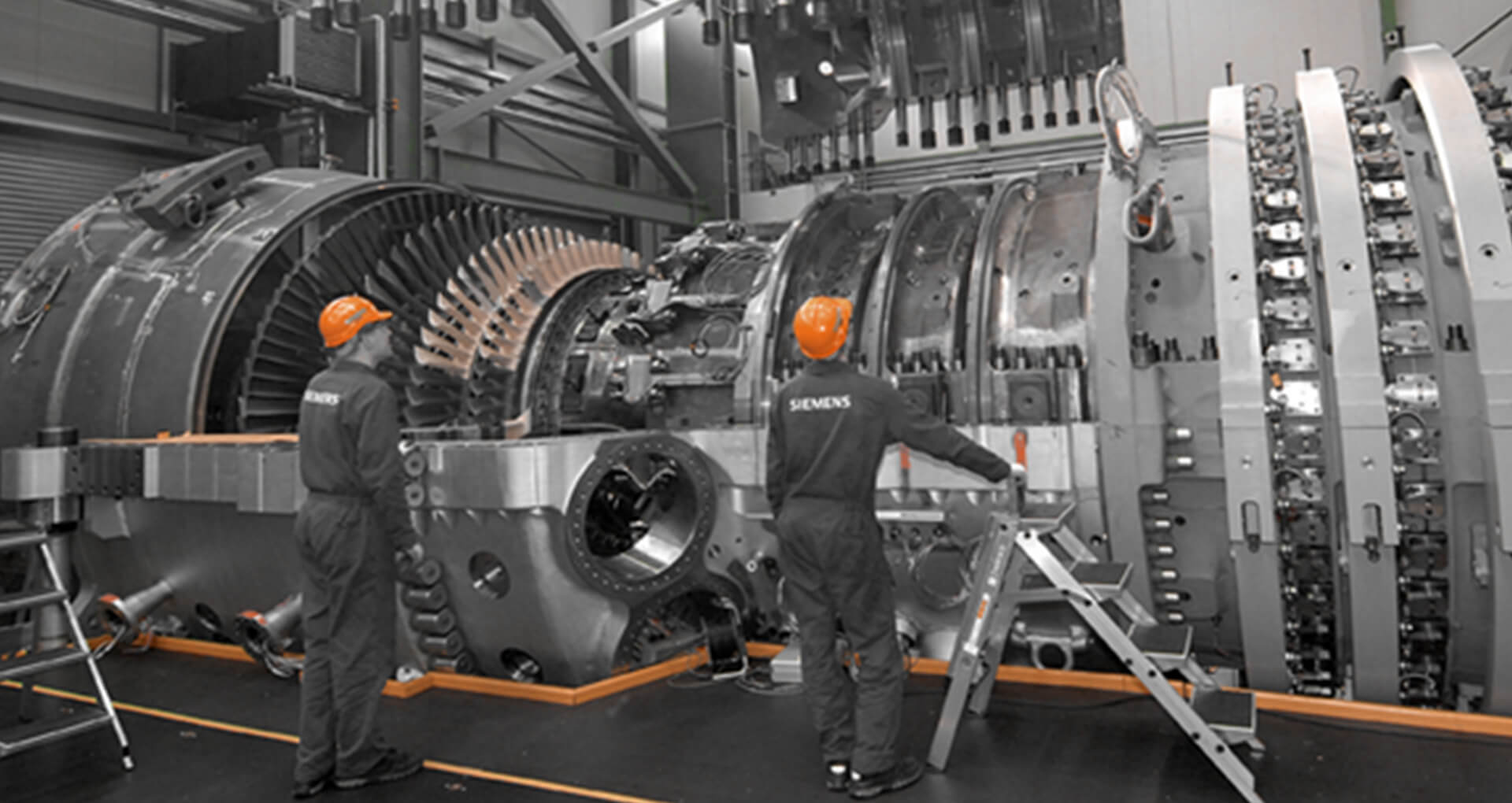

Welding and alignment equipment for gas and steam turbine manufacturing

For the energy segment, HAANE welding systems offers solutions for welding-related production tasks.

In the field of power plant construction, we have delivered welding systems for steam and gas turbine engineering, for the rotors as well as for the turbine housings. This includes connection welding as well as overlay welding.

The weld overlay system delivered by HAANE welding systems has a high level of automation in order to produce defect free welding, which is needed for the rotors to ensure and maintain their fatigue strength.

Alignment devices of very high accuracy for connecting turbine components are also in our delivery program.

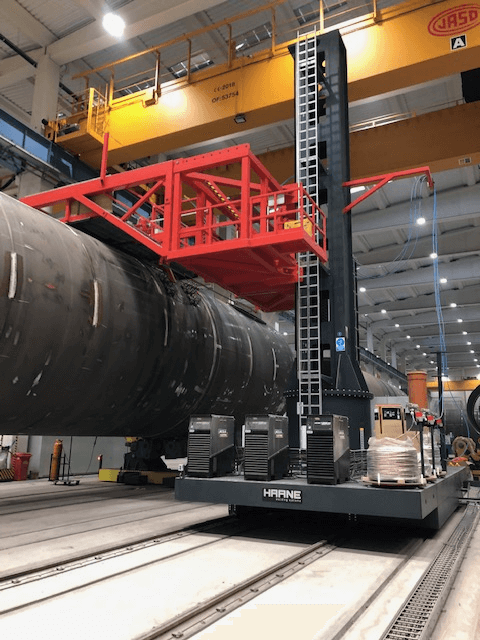

Welding and alignment equipment for wind tower production

HAANE welding systems offers complete welding production lines for manufacturing of wind towers, which are used in wind turbine generators (WTG). This includes inside welding booms, outside welding platforms, rotators and fit-up units used in growing lines.

Welding of heavy vales for high pressure applications

Large nominal diameters at high pressure valves usually result in large wall thicknesses and weights. The rotation needed for welding needs to manage remarkable eccentric loads must be done without jerk.

HAANE welding systems offers a lathe type welding positioner, consisting of a headstock which supplies a high torque and a back slash free for the rotation drive. The tailstock is adjustable in distance and equipped with a pressing sleeve. The table plate of the headstock is of large diameter and very stable and the clamping slides are prepared to hold the jaw boxes.

The welding installation can easily be operated by a Siemens PLC. Any maintenance work can be done by using a service platform in a very ergonomic way and in compliance with OHSAS regulations.

The welding process in use is a HAANE Multi-Mode SAW. For the first layers in the root area SAW single wire is used for getting a good penetration and a good slag release. For the fill layers SAW Twin process is used for lower heat input and higher deposit. The change can be done within seconds and with no need of changing any components.