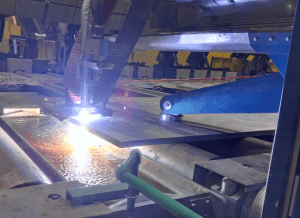

Mechanized plasma cutting applications

Alongside casting, cutting and welding are the techniques which allow the designer to also realize the technical implementation of his complexly created, multidimensional structures. In the case of large and heavy components, very frequently many welds must be set which must be welded in vertical or overhead positions if the component cannot be positioned differently. Such out-of-position welding however greatly reduces the deposition rates and mostly does not permit the use of productive, mechanized high-performance welding processes.

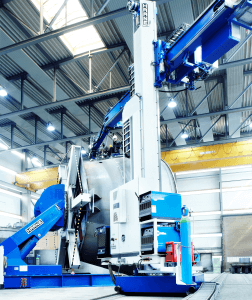

HAANE welding systems offers a full range of various positioners for such workpieces the purchase of which can be amortized quickly (turn tables and roller stands).

We also provide welding machines for mechanized and automated welding which due to their high deposition rates significantly reduce the welding-related production times in heavy engineering.

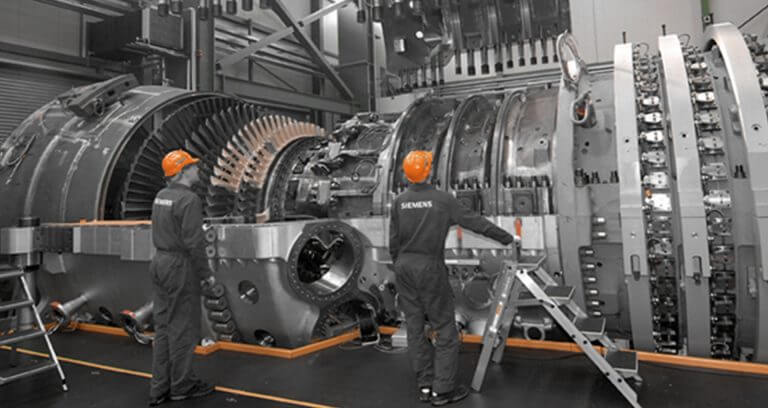

Heavy Industry

Steel constructions in heavy industry must be manufactured in due time, even if they are huge in size. Welding is one of the major processes involved in the manufacturing process. So, the welding process must be efficient, which means, turn the workpiece into best welding position, use a high deposition welding process and avoid none-arc times. HAANE welding systems knows how to arrange this.

Heavy duty vehicles

Heavy duty vehicles are custom designed for an optimal accomplishment of their purpose. They are huge and heavy, have high wall thickness and the vehicle body is complex in his structure.

Such structures are predestinated to be welded by making full use of a positioner bringing the joint into best possible position for efficient welding.

HAANE welding systems has delivered such positioners for production of mining machinery. Hydraulic clamping devices can be included. A very special design guarantees the occupational safety for the welder in any event. A two-dimensional clamping device is available in case of robot application.

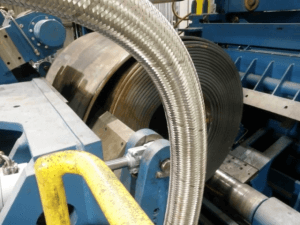

Equipment for welding of wheels for such vehicles for agriculture, forestry or military, inside and outside at the same time, is also our business.

Fully automated production lines for heavy duty axles have been delivered by HAANE welding systems.

Cement and steel works

Typical products for this segment are welding stations for build-up welding at casting rolls. Reconditioning by resurfacing is cost efficient.

There are also mechanized and automated cutting applications as the Plasma cutting of very hot slabs and sampling of steel coils by automated plasma cut operation, coil cutter.