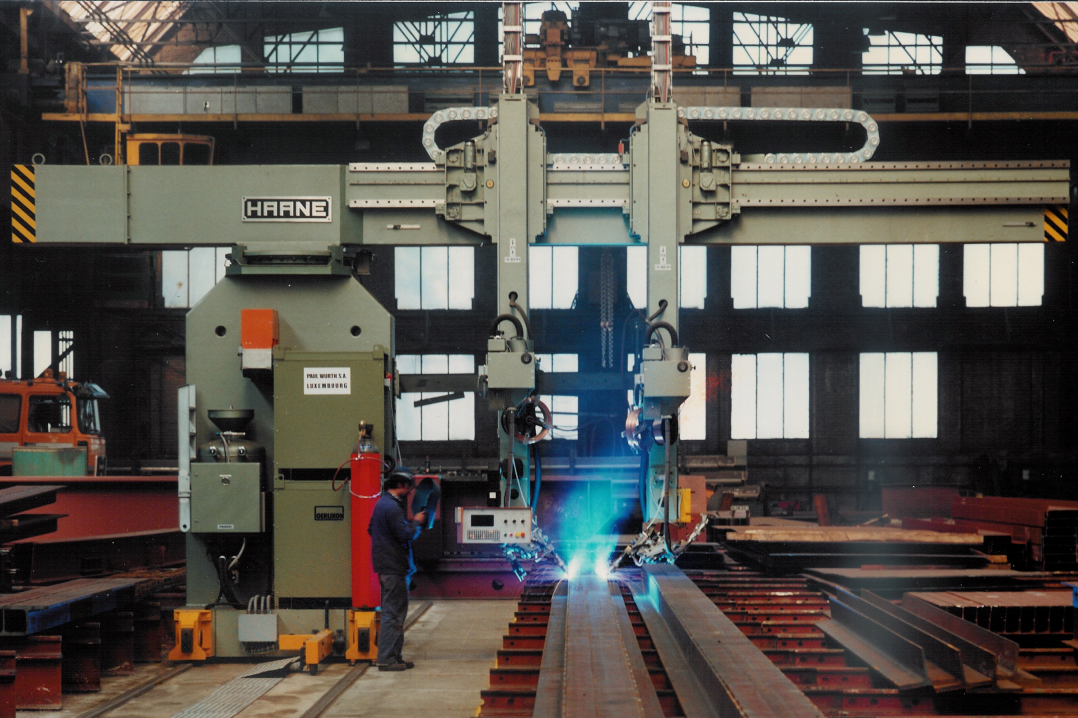

Customized cantilever welding machines

HAANE welding systems supplies highly productive customized welding systems to produce beams and profiles needed in steel construction, bridge construction, rail vehicle construction and hydraulic steelwork.

Welding of I-Beams and H-Beams

Due to our inhouse design and manufacturing facilities we can offer customized solutions for welding equipment matching your individual production situation in an optimal way.

Double head welding stations, cantilever type, have been proven successful for the manufacturing of beams used in steel building construction and bridge construction. Welding can be done either in standing or in lying beam position.

A cantilever design of the welding machine is very popular, because it can be parked into a small space, if necessary, to not disturb workpiece handling operation in the production.

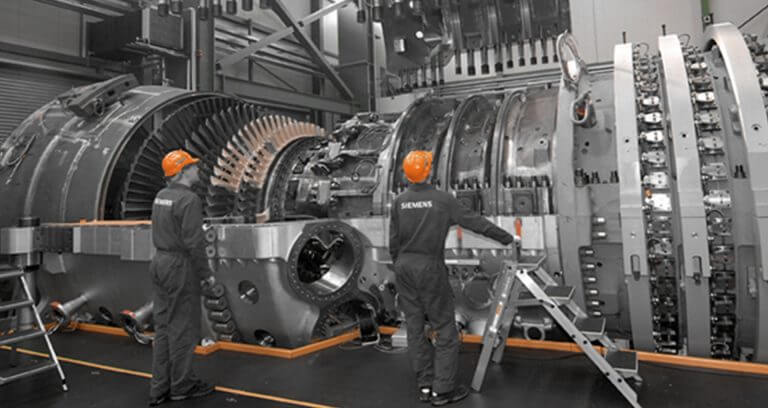

Welding of structural Box Beams

The wall thickness of box beams used for bridge construction can be quite high. For a quick delivery in a project a highly productive welding system is needed, for example with two welding heads, each of them can run SAW-Tandem-Twin technology with AC/DC welding inverters. Then 8 wires are in the game presenting an impressive welding deposition rate.

For keeping the non-arc-time as low as possible and the duty cycle of the machine as high as possible, the carriage speed is boosted up and the consumables are supplied from bulk packs, e.g. 8 non-rotating drums with 300 kg each.

Welding of Aluminium Profiles

Fully automated SAW Welding

Submerged Arc Welding SAW can be done fully automatically, if you take care of flux supply, sieving off flux from slag, recovery of flux, release of slag, removal of slag, automatic wire cutting a.o.m..

HAANE welding systems knows how to do this and also takes care of fine dust prevention resulting in a complete welding production cell.

Welding of interlocks onto tubular combined walls

For hydraulic steelwork, sheetpiling and pipe walls, often tubular combined walls are used. For welding the needed interlocks to the pipe, HAANE welding systems can offer a cantilever type welding machine with very high productivity.

A big pressure tank for the flux supply and bulk packs (drums or coils) for the wire keep the machine just go on and on.