Welding of stainless steel in food and pharmaceutical industry

HAANE welding systems manufactures solutions for apparatus and plant construction which are perfectly tailored to the customer’s demands. High-quality, valuable products are frequently manufactured, where any damage during handling or welding might prove costly. Often a prompt remanufacturing represents a major problem due to procurement difficulties. Therefore, the apparatus and plant construction are business sectors where one is never satisfied with an approximate solution (e.g. 80% acc. to Pareto principle) but must find the very best solution, 100%!

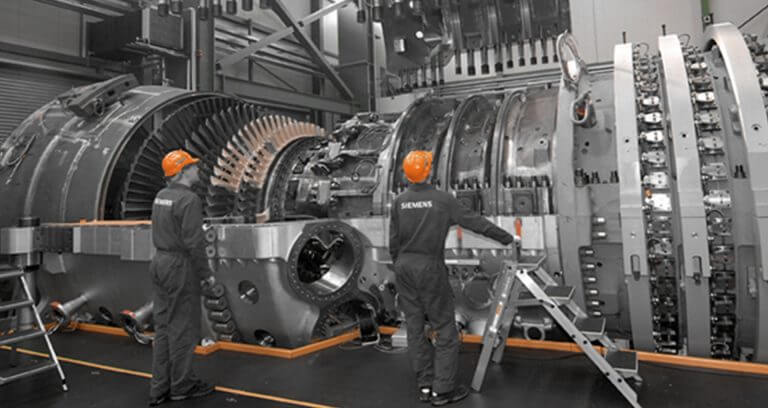

High pressure vessels, reactors, columns, converters, autoclaves

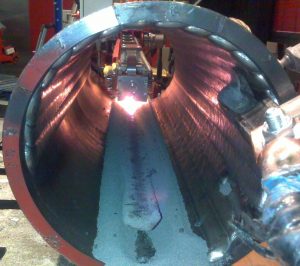

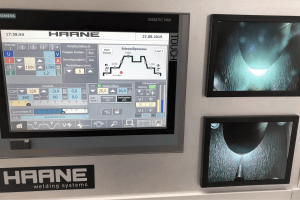

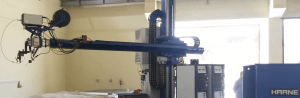

To produce pressure vessels, reactors, columns, converters and autoclaves HAANE welding systems designs and manufactures customized welding automation equipment of different variants, always considering the solution must guarantee high productivity and efficiency. We always have workplace safety in mind, and we follow relevant occupational health and safety regulations (OHSAS) and ergonomic principles.

A good example for a customized solution is shown in picture 1:

For space-saving reason the manipulator is designed as a monorail welding platform. An elevator for 2 persons plus tools either leads the welder to the first level where he can approach the workpiece in a conveyor cage and tack-weld by using the GMAG welding process. Or he can reach the second level which leads to the platform from which the welds can be completed by means of the SAW tandem welding procedure.

This SAW tandem welding installation has been designed to produce autoclaves with a diameter close to 10 m.

Stainless steel use in food and pharmaceutical industry

Apparatuses built for food or pharmaceutical industry are mostly made of stainless steel. HAANE welding systems designs and manufactures welding automation equipment using GMAW, TIG, TIG focused arc and Plasma as welding process.