The industrial world is evolving – and so are we.

While we help shape the future, one thing remains unchanged: the quality of our solutions. From turbine manufacturing to wind power technology, we offer technical expertise tailored to your industry. Our extensive portfolio includes customised systems that empower you to master your sector’s challenges with confidence.

Haven’t found the right solution for your industry yet? We’ll work with you to develop a tailor-made system that prepares you for Smart Factory of tomorrow. We look forward to getting to know you.

Let’s start the journey together.

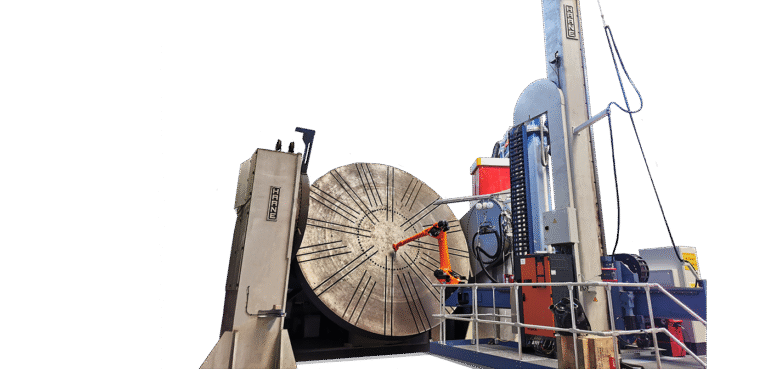

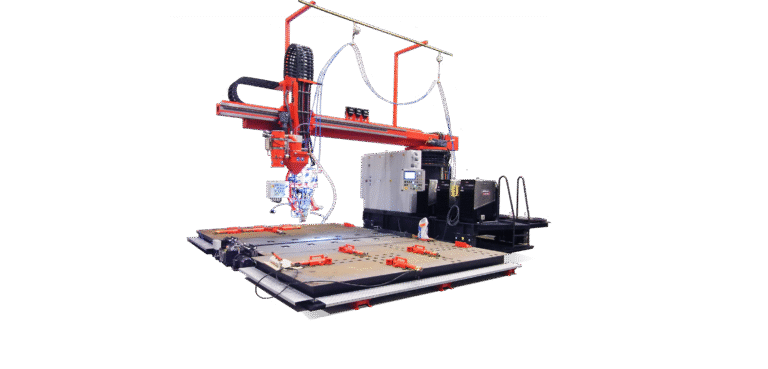

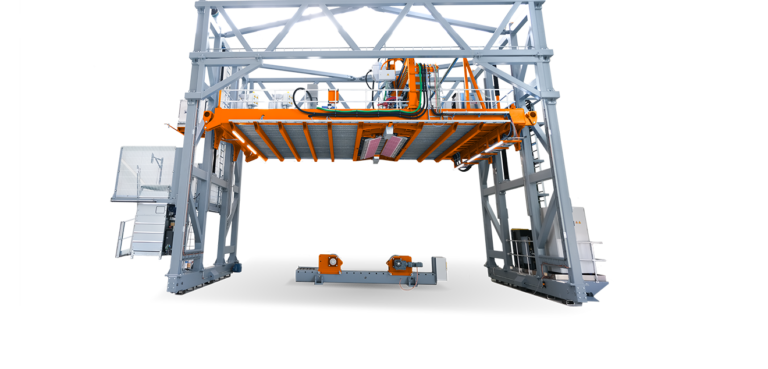

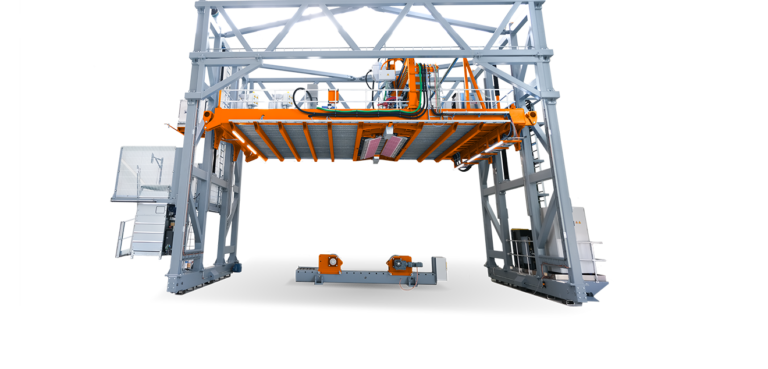

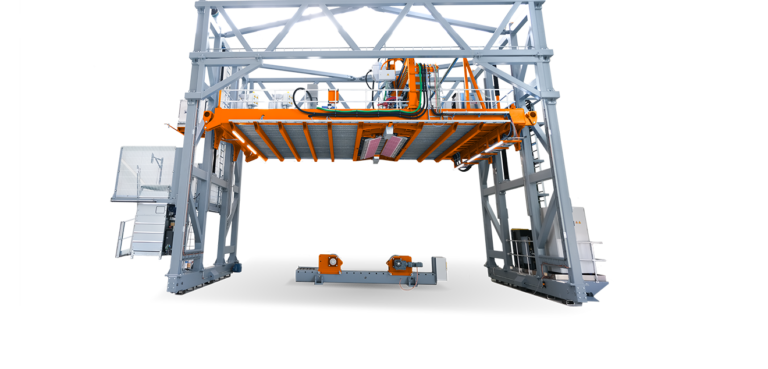

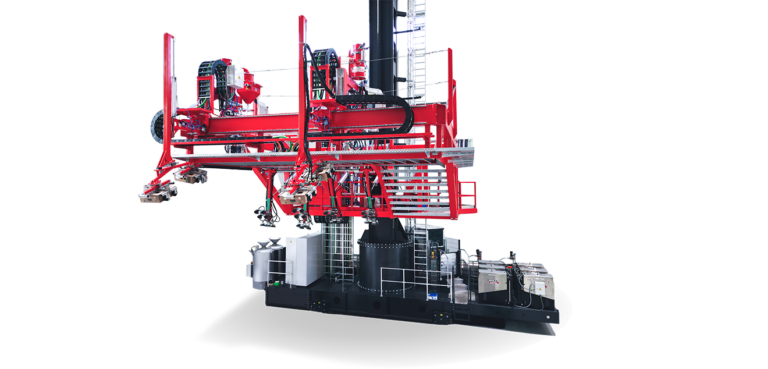

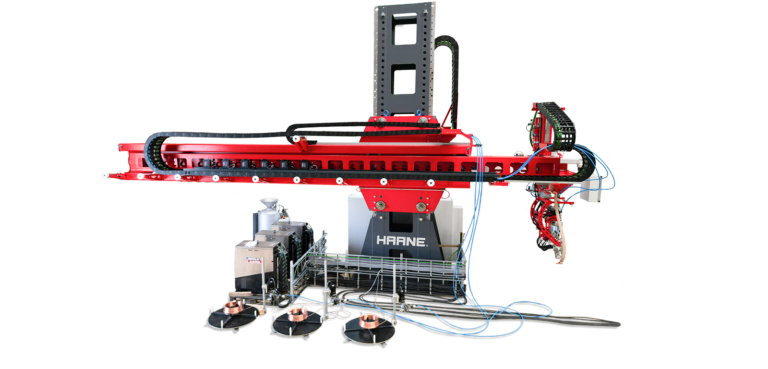

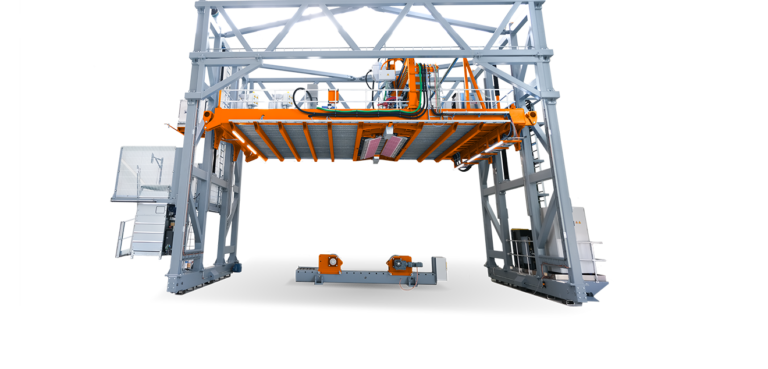

Offshore structures must withstand extreme conditions and require the highest manufacturing quality. We supply high–performance welding equipment and handling systems for Monopiles, deep–sea components and underwater pipelines that meet DNVGL–ST–F101 and DNVGL–OS–C401 requirements.

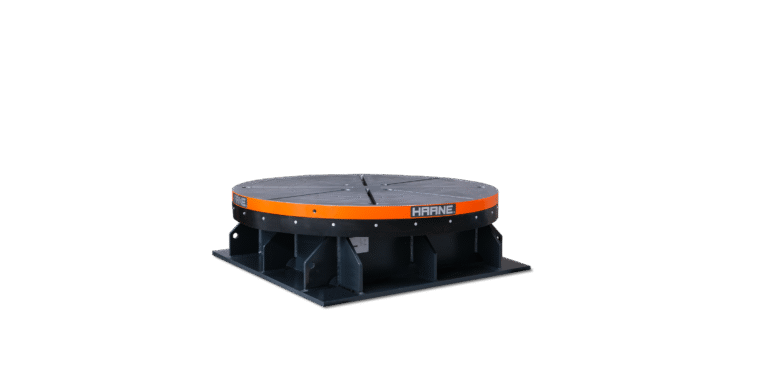

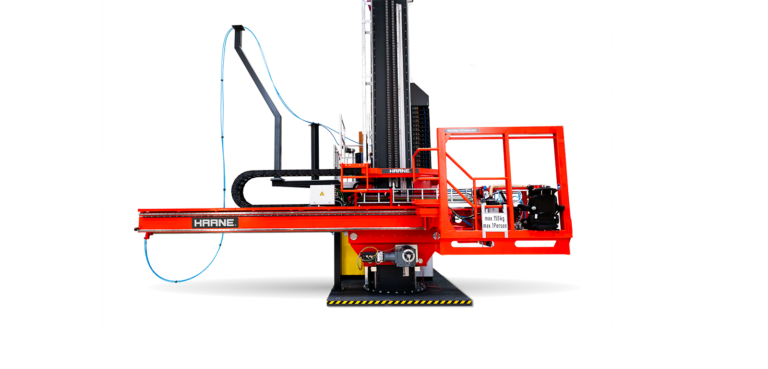

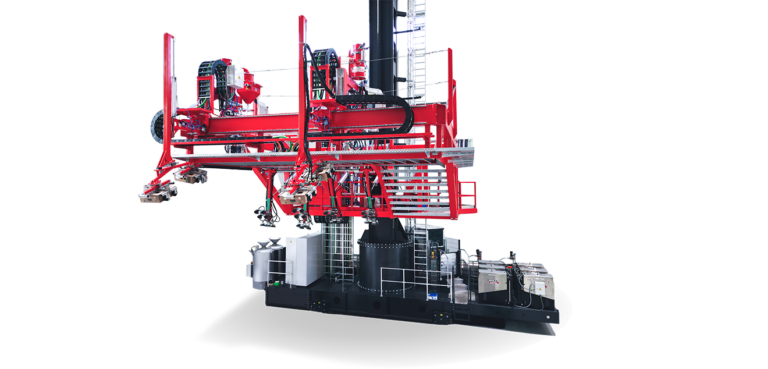

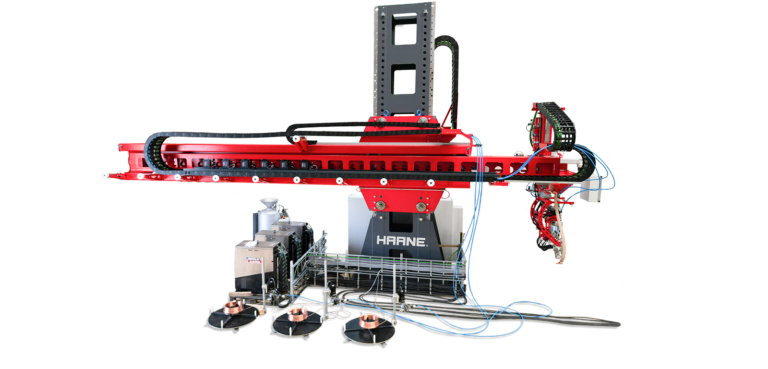

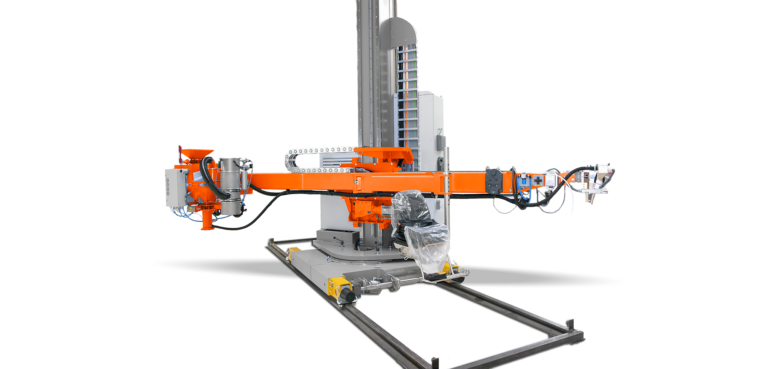

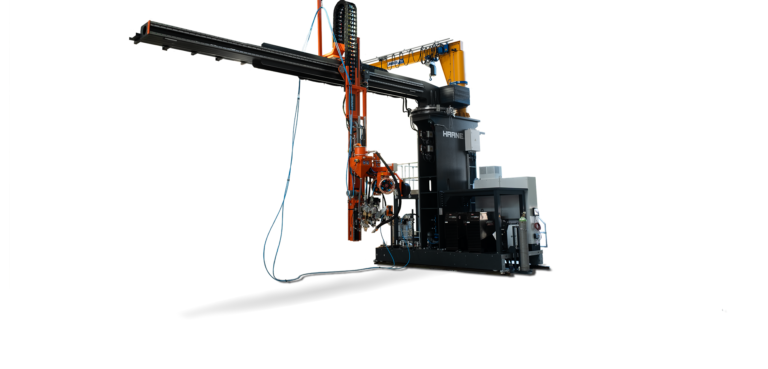

Our solutions include welding platforms with high performance welding heads, assembly rollerbeds, plate jointing stations and column and boom systems with telescopic booms for internal and external welding. Whether stationary or mobile, our systems are designed for the most demanding manufacturing processes with extreme weights and sizes – for example, production lines for XXL Monopiles.

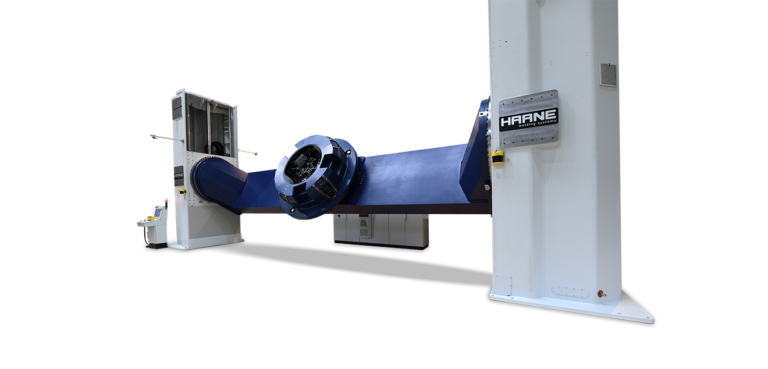

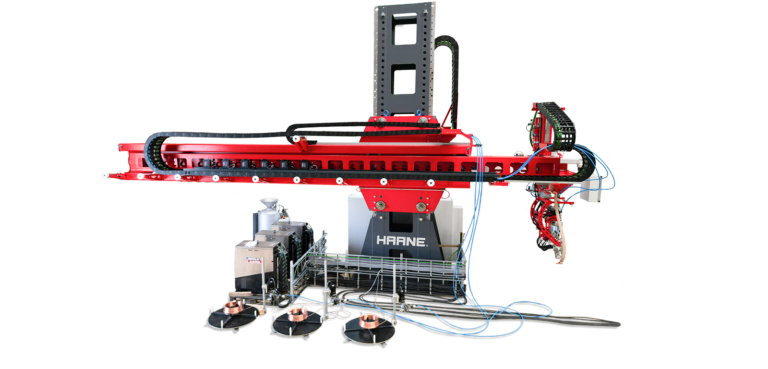

True to our “one-stop solution” approach, HAANE delivers turnkey design and implementation of welding systems for the construction and conversion of submarines. Our systems are built with Smart Factory principles in mind – designed for durability, sustainability, and future readiness.

With our extensive project experience in the defense and security sector, we ensure strict confidentiality and the highest security standards.

The HAANE portfolio covers the following production steps:

We design and manufacture systems:

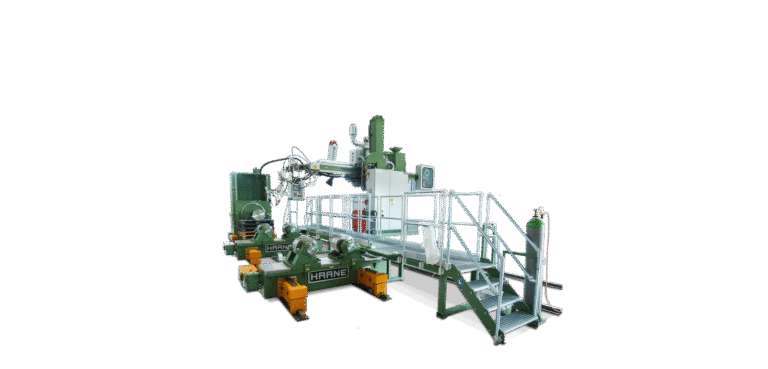

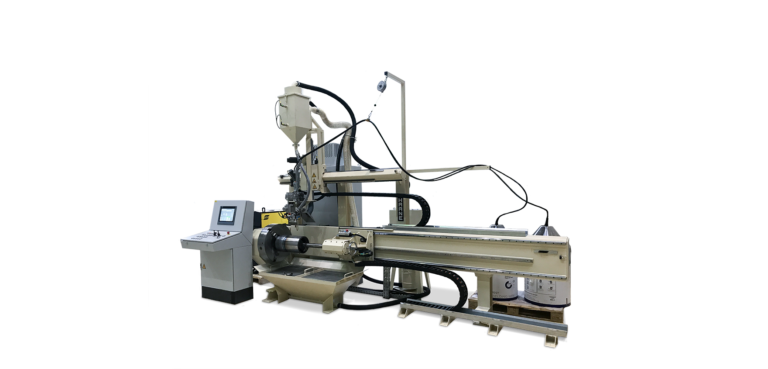

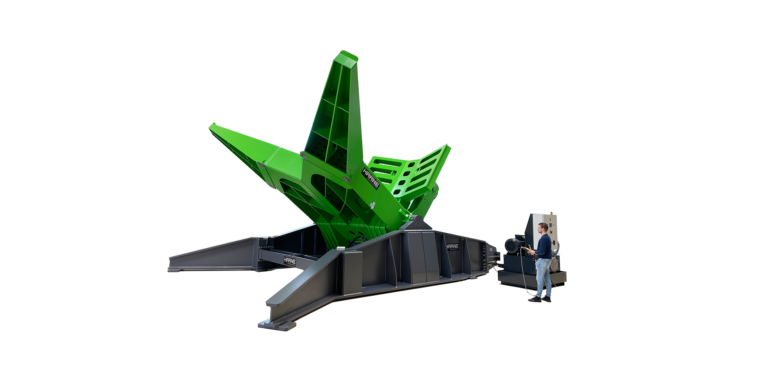

The welding of pressure vessels, reactors, columns, autoclaves, and valves requires highly precise machinery. To ensure consistent quality, HAANE welding systems are designed and manufactured with the utmost care. During production and component selection, we focus on maximum reliability and absolute precision.

Our solutions for stainless steel in the food and pharmaceutical industries:

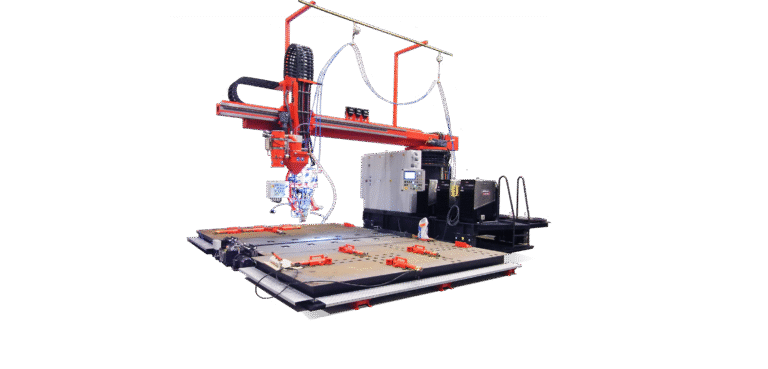

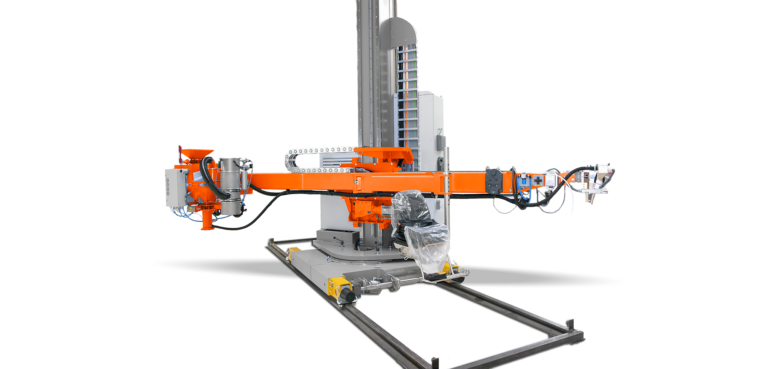

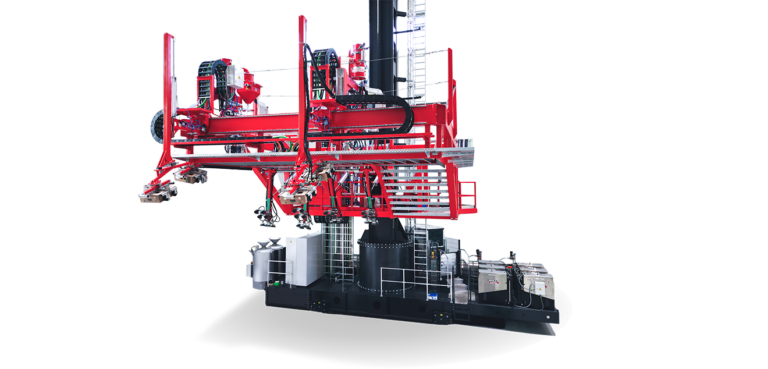

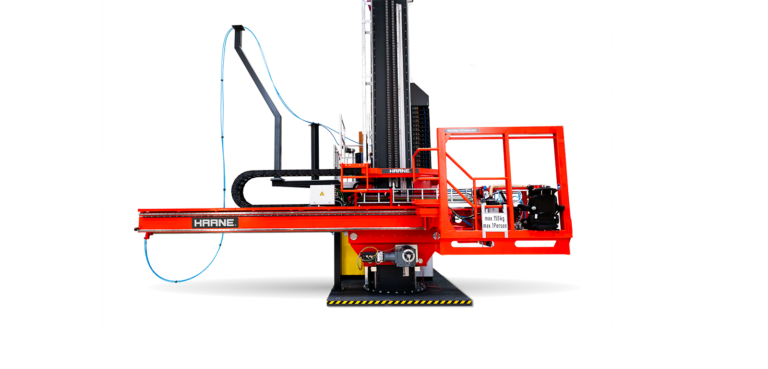

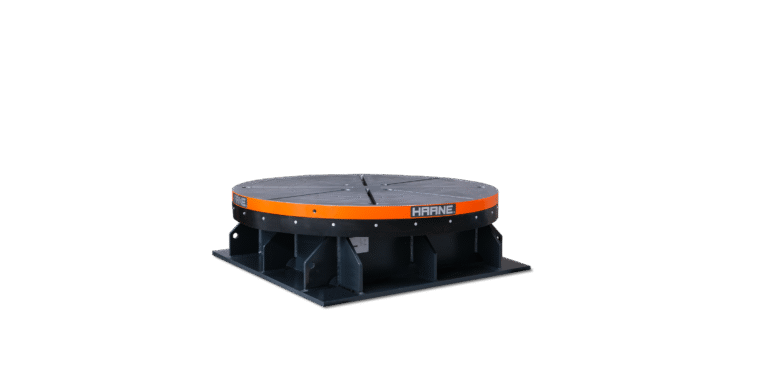

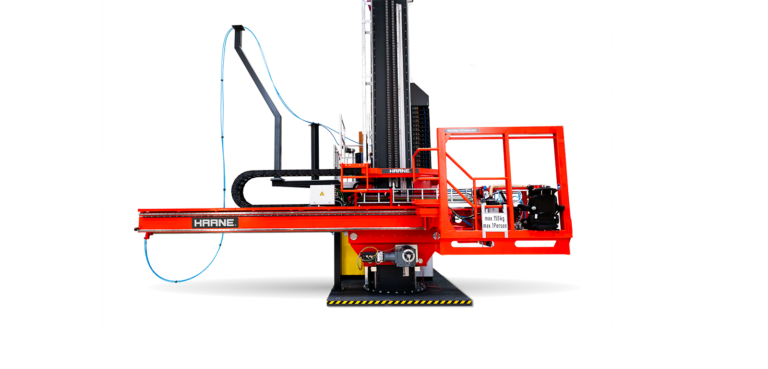

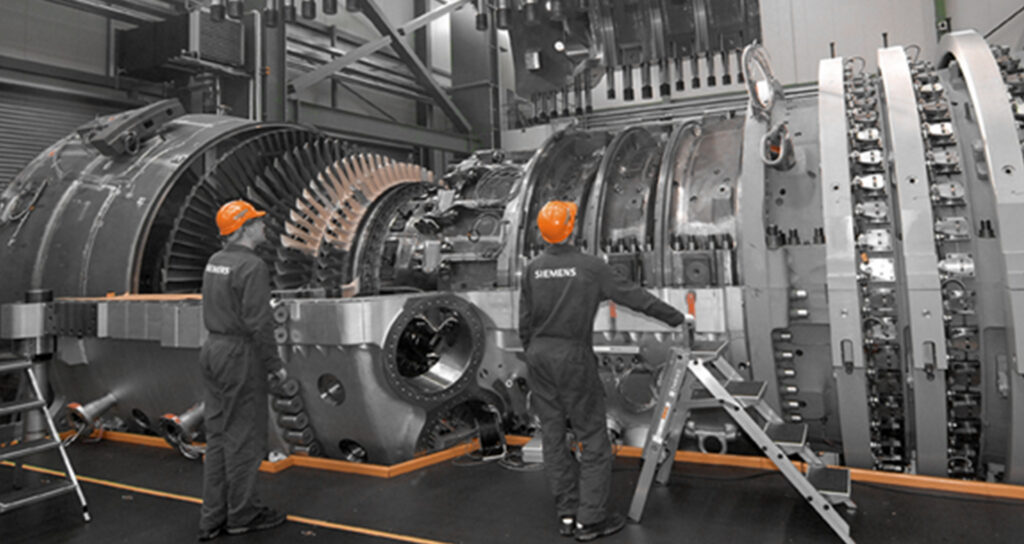

HAANE delivers highly productive, custom-engineered welding systems and handling systems for the production of gas and steam turbines – both for rotors and casings.

Thick-walled high-pressure valves can be efficiently manufactured using our multi-mode SAW welding head, which allows for rapid and effortless switching between single-wire and twin-wire welding without changing components.

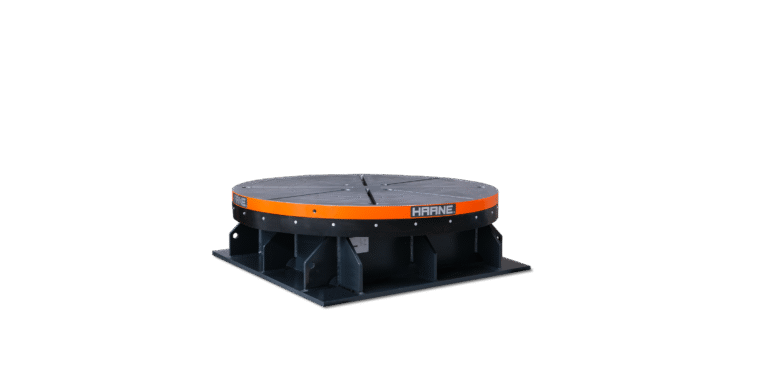

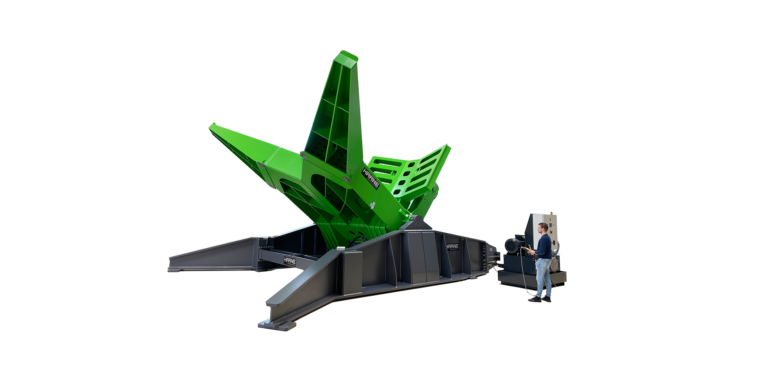

In the field of renewable energy generation, HAANE welding systems provides welding and handling equipment for the construction of wind turbines.

Our solutions for the manufacturing of turbine rotors and casings: