Scan

Automated Layer Build-Up

Adaptive Adjustments

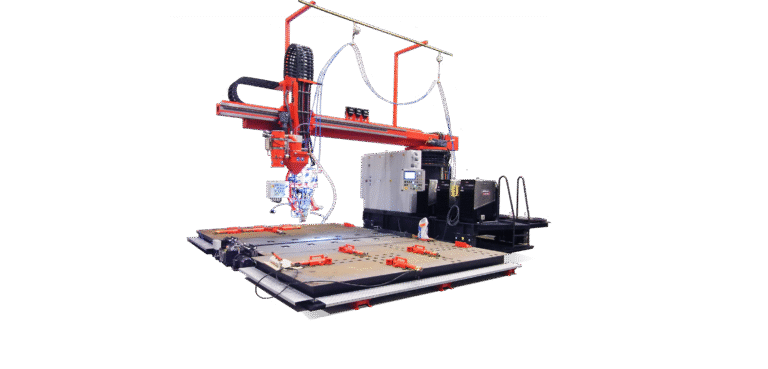

Using a detailed laser scan, the system analyzes the geometry of the weld seam (Narrow Gap Groove) and calculates the optimal welding parameters and pass positions based on the Welding Procedure Specifications (WPS).

The system automatically adjusts welding parameters and welding head angles to account for tolerances such as roundness deviations, rolling tolerances, and pass errors. This ensures a consistent and high-quality welding process.

The integration of multiple welding heads allows different tasks to be performed simultaneously. This significantly increases productivity without compromising precision.

Despite the complex technology, the system offers a user-friendly interface that can be specifically tailored to the needs of the operators and the production environment. Extensive programming knowledge is not required.

Thanks to online access, technicians can remotely diagnose and resolve issues without interrupting the production process.

In addition to high-quality electronic components, we focus on user-friendly wiring. Cable chains and a well-thought-out design minimize strain.

Slide für mehr Branchen

HAANE designs and builds welding applications for everything from monopile production to welding systems for offshore laying vessels. Whether individual machines or turnkey factories – with our many years of experience in special machine construction, we offer tailor–made solutions and respond flexibly to your needs.

Slide für mehr Branchen

Our machines provide reliable solutions for the welding and assembly of submarines. We operate to the highest standards of quality and secrecy in the defense industry and ensure precise manufacturing processes.

Slide für mehr Branchen

Whether mobile or stationary, our spiral pipe welding systems enable precise and efficient production of tubes for a wide range of applications. Thanks to state–of–the–art technology and thoughtful design, they meet the highest quality standards and offer flexible solutions for demanding projects.

Slide für mehr Branchen

With simultaneous welding heads and a wide range of welding processes, we optimize performance in steel, bridge and rail construction. Our technologies enable precise, fast and economical welding processes for maximum efficiency in any application.

Slide für mehr Branchen

For the food and chemical industries, we provide precision solutions for the manufacture of containers and valves. Our technology ensures long–lasting welds and optimized production processes.

Slide für mehr Branchen

HAANE provides future–proof welding and handling systems for the construction, maintenance and repair of turbines, high–pressure valves and wind turbines. Our solutions improve the service life of power generation equipment through the highest manufacturing precision and quality.

Slide für mehr Branchen

HAANE offers handling equipment such as Positioners and Rollerbeds as well as mechanized and automated welding equipment that shorten manufacturing times in heavy machinery construction. Our solutions are successfully used in areas such as utility and heavy–duty vehicle construction and in overlay welding in cement and steel plants.

Individuality and flexibility are our great strengths. Are you working on a project? Together, we develop efficient and forward-looking solutions to your challenges. We would be pleased to engage in a personal discussion.