Double Jointing of Steel pipes

At a pipe laying job the double jointing DJ of pipes can be a good choice for accelerating the progress of the pipe laying whilst improving quality of the welds at the same time.

Double joint stations are designed to produces pipes of 2×6.000 mm and 2×12.000 mm length.

HAANE welding systems supplies double joint stations starting for pipes dia 10” pipes using the submerged arc welding process inside and outside.

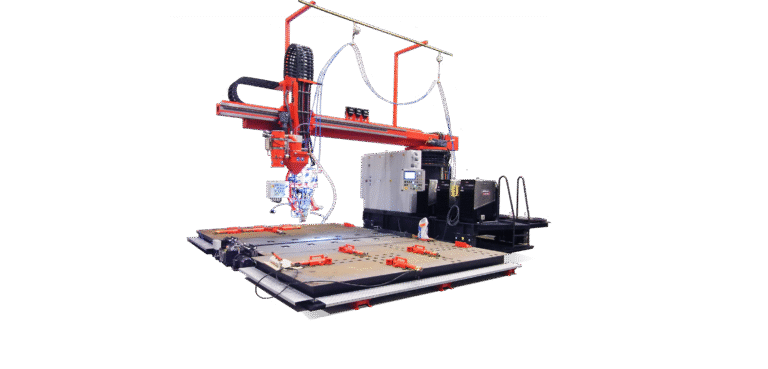

HAANE welding systems supplies entire pipe double jointing systems, consisting of:

LINED and CLAD pipes are perfectly combining two features: Corrosive resistance and very good mechanical properties with cost advantage compared to solid/pure CRA pipe materials.

At mechanically LINED and as well at metallurgically CLAD pipes the circular seam at double joining must have the same good CRA properties as the liner or CLAD inside the pipe.

Inside electro strip cladding ESW is a good process to do that job. It can be used for pipes down to 12” size and 2 x 12.000 mm length. Typical strip widths are 15/20/30×0,5 mm and typical alloys type 625, 825, 316.

Deposition rates of 6 – 12- 24 kg/hour can be reached and quite often only one layer is sufficient to meet the requirements.

HAANE welding systems can deliver the entire system needed, consisting of: