Overlay Welding & Cladding with HAANE Solutions

Overlay welding generally means applying an extra layer to a metal base material using a welding procedure with the objective of achieving a higher wear resistance against abrasion, erosion, cavitation and corrosion (CRA).

The nature of the materials to be applied (e.g. hard surfacing, manganese hard steels, austenites, nickel-base alloys, inconel, cobalt-base alloys, stellites and many others) is determined by the contact media and the prevailing application conditions such as pressure and temperature.

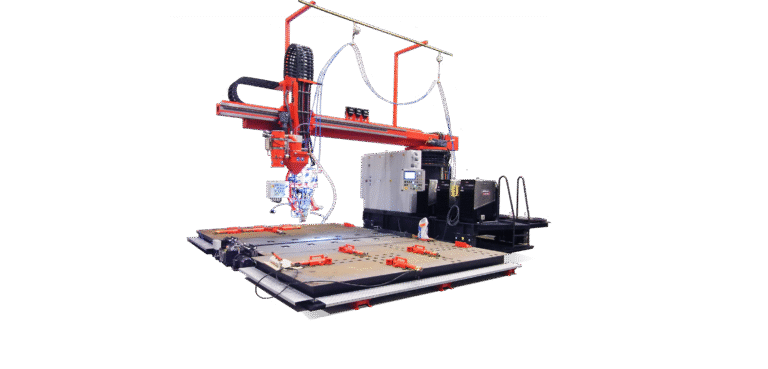

HAANE welding systems adopts all established and modern welding methods in order to develop comprehensive customized production facilities for your welding production process.

Also shape welding, for repair purposes – recovery of the old outline, as well as for the purpose of new parts is carried out. Here the final contour of the finished part is manufactured very economically because local increases of material are not achieved by removing the large remainder but by adding, i.e. applying the small raised area, e.g. applications for grout joints at monopiles.

Weld overlay of a metallic layer on a base material by using the arc welding processes SAW, GMAW (MIG-MAG) or Plasma / TIG. In order to achieve desired properties the weld deposit may be of different chemical composition, or may be of the same chemical composition as an “Additive Manufacturing” process.

The picture shows the pre-programmed, fully-automatic weld overlaying of the turbine rotor bearing area, for achieving a different chemical composition than the base material 1.4906 (X12 CrMoWVNbN 10-1-1).

Strip cladding following the electro slag welding procedure (ESW), inside and outside, pipes, nozzles, metal sheets, vessels, base plates.

Armour plating (hard surfacing) of metal sheets and pipes.

Plasma transferred arc welding (PTA) to close the inner cladding of the pipe at the weld seam.

Laser overlay welding installation (multifunctional system) to apply a high-temperature resistant wear layer of a cobalt-base alloy.